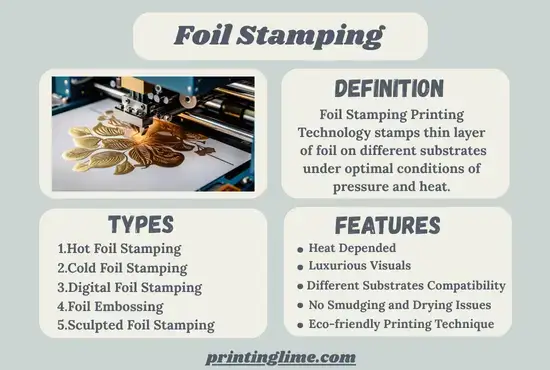

Foil Stamping or hot stamping printing technology can be defined as a luxurious printing technique that uses heat and pressure to print thin foil layer on materials; i.e; paper, cardboard, leather, and plastic, etc. It means that this technique has optimal heat and pressure conditions to print.

How Foil Stamping Printing Technology Works?

Following steps are carried out while printing images and text in foil stamping printing technology.

Design Preparation and Die Creation

The first step in foil stamping printing technique is the preparation of vector file using software like Adobe Illustrator. For high-quality precise design, vector graphics are very crucial because they define the sharpness of design edges.

After preparing the design, metal stamp has been created that has text and artwork engrave on it. The die may be of different metal materials such as brass, magnesium, or copper, etc.

Foil Selection and Setting

After creating the design die, different foils are selected for getting desired silver or gold finishes along with intended matte, gloss, holographic, or clear effect. Each foil is consisted of 3 layers: polyester carrier layer, adhesive layer, and colored or metallic layer.

After selecting the desired foil, the foil is then loaded into the foil stamping machine. When the printing process is started, then foil from the stamping machine unwinds, and takes the position between the die and the printing substrate. The unwind foil precisely aligns itself with die and substrate so that image and text print in correct positions.

Heat and Pressure Application

After adjusting the foil between the die and substrate, rightly, the foil stamping machine starts to provide heat to the die so that it activates and presses the foil down onto the substrate. On heating, the adhesive layer of the foil starts to melt and due to applied pressure, the adhesive layer permanently bonds to the substrate according to the engraved design of the die.

The foil is transferred to the substrate following the Selective Transfer Process, thus ensures the clean and sharp print design. The unused foil either again rewound itself into the foil stamping machine, while residues after completion of printing process goes to trash.

Images and Text Printing on Substrate

Foil Stamping Printing Technology has the ability to produce very high-contrast prints that gives very fine details of intricate typography and small fonts. Because on heating and getting pressure, foil sits on the substrate very elegantly to print images and text.

The ability of foil to sit down on the substrate instead of absorbing in it, makes this printing technique best for highlighting the brand names, monograms and borders on business cards, book covers, packaging, and certificates.

Finishing

For best finishing to the product, you can also apply other printing techniques along with it. These additional printing techniques like embossing or debossing can define dimensions of design in more details. Because both these printing technologies can give more raised effect to images and text, thus give more tactile and visually dynamic effect to the design.

On the other hand, you can also get multi-colored foils in layers by doing multi-pass stamping with other techniques such as offset or spot UV coating.

Types of Foil Stamping Printing Technique

Foil Stamping can be done by following ways, or you can say it has following different types.

Hot Foil Stamping Printing Technique(Traditional)

Hot Foil Stamping is the traditional way of stamping foil on the substrate through appropriate application of heat and pressure. On getting heat, the foil activates and sticks to the substrate according to the engraved design on the metal die. This foil stamping type is best for printing luxury packaging, wedding invitations, business cards and book covers. Because it is best for gold and silver printing on substrates such as paper, leather, or plastic.

Cold Foil Stamping Printing Technique

The cold foil stamping technique uses UV-curable adhesive instead of heat for stamping foil on substrate. At first, a UV-curable adhesive that would be similar to the metal die design is applied on the substrate and then foil transfers with the printing press. This stamping method supports foil printing on thin materials that may not resist to heat.

Moreover, this technique supports CMYK overprinting for getting colorful metallic effects, so it is highly used for printing multi-colored magazines, labels, and consumer packaging.

Digital Foil Stamping Printing Technique

The foil is applied to the substrate by using computer instead of metal dies. Actually, at first, adhesive toner or ink is applied to the substrate on which the foil is applied with digital foil stamping machine.

During this technique, heat and pressure is used to activate the foil that sticks to the adhesive toner or ink. This type is best for printing variable data such as names, serial numbers, etc. Moreover, it is very cost-effective for printing customized invitations, and certificates because it eliminates the cost of metal die.

Foil Embossing Printing Technique

This type is the combination of foil stamping technology and embossing. This type of foil stamping is especially used when the purpose is getting the tactile and visual depth in printed images or text. Due to this feature, this stamping technique is highly used to give luxurious, high-end finishing to material that has especially been used for branding purposes, such as labels, stationery, etc.

Sculpted Foil Stamping Printing Technique

It is the most specialized technique that was used for sculpting foil on substrate to get 3D design print. This printing method involves the creation of custom-engraved dies having multiple heights and contours. It is the best foil printing technique to print labels, and luxury packaging.

Key Features of Foil Stamping/ Hot Stamping Printing Technique

Following are the key features of Foil Stamping Printing Technique.

Heat Depended Printing Technique

One of the most important feature of foil printing technique is that the whole printing process is totally depended on the heat. Actually, firstly the die is heated, and then it pressed against the foil. On pressing, the adhesive layer of the foil would stick to the substrate according to the design of die. During the whole printing process, heat ensures the durable clean metallic print.

Luxurious Eye-catching Visuals

Foil Stamping allows printing with a number of different metallic and colored materials. For example, you can use gold, silver, or bronze foils for getting high impacted shiny finishes. Moreover, for visual appealing, it offers different choices such as matte, gloss, holographic, and pearlescent.

Produce High-Quality Precise Printing Results

As foil stamping can produce best quality results so it is best for getting intricate designs that have fine details with high-quality vector artwork. Moreover, the ability of this printing technique to produce sharp shinny designs along with matte or dark background, makes it best for making logos, names, and other printable designs more attractive.

Support Compatibility with Different Substrates

The hot stamping printing technique has the ability to print on different types of substrates such as paper, cardboard, leather, plastic, wood, and fabric. So, this feature makes this technique to be highly used for luxury packaging, greeting cards, book-covers, and certificates.

Compatible with Other Printing Techniques

Foil Stamping can also be used with other printing techniques for getting tactile depth in printed designs. Moreover, the collaboration with other printing techniques enhances the visual and physical experience along with producing multi-layered designs.

No Smudging and Drying Issues

Since the whole printing process is totally depended on heat and pressure, so foil stamping technique has no issue of smudging. Moreover, as it does not use any ink, so printouts do not need time for drying.

Best Eco-friendly Printing Technique

It is one of the best eco-friendly printing technique because now the modern foil stamping technique uses non-toxic foils and encourage minimal waste production. Moreover, it is heat-supported technique. So, there are no chances of fading, scratching, and peeling off the adhesive foil in harsh environmental conditions.